- Foundation

- Actions

- Osteoarthritis

- Osteoporosis

- Actuality

- OAFI Radio/TV

- Get Involved

- Contact

-

-

-

OAFI

Osteoarthritis International FoundationC/ Tuset, 19 · 3º 2ª

08006 Barcelona

(+34) 931 594 015

info@oafifoundation.comSchedule:

Monday-Thursday 9AM-6PM

Friday 8AM-3PM

-

-

-

-

-

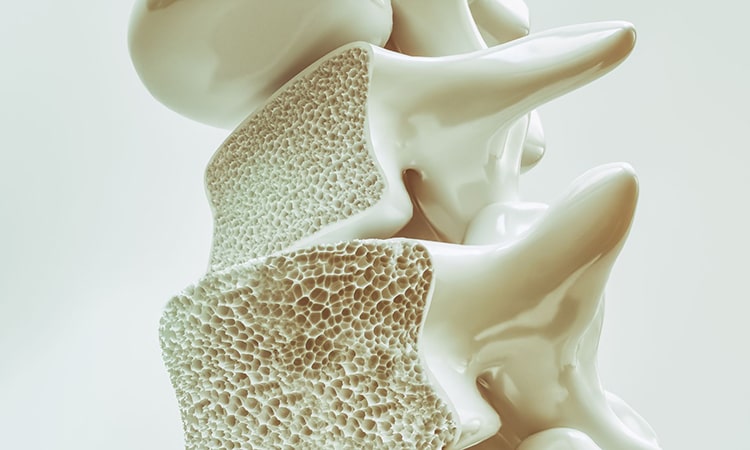

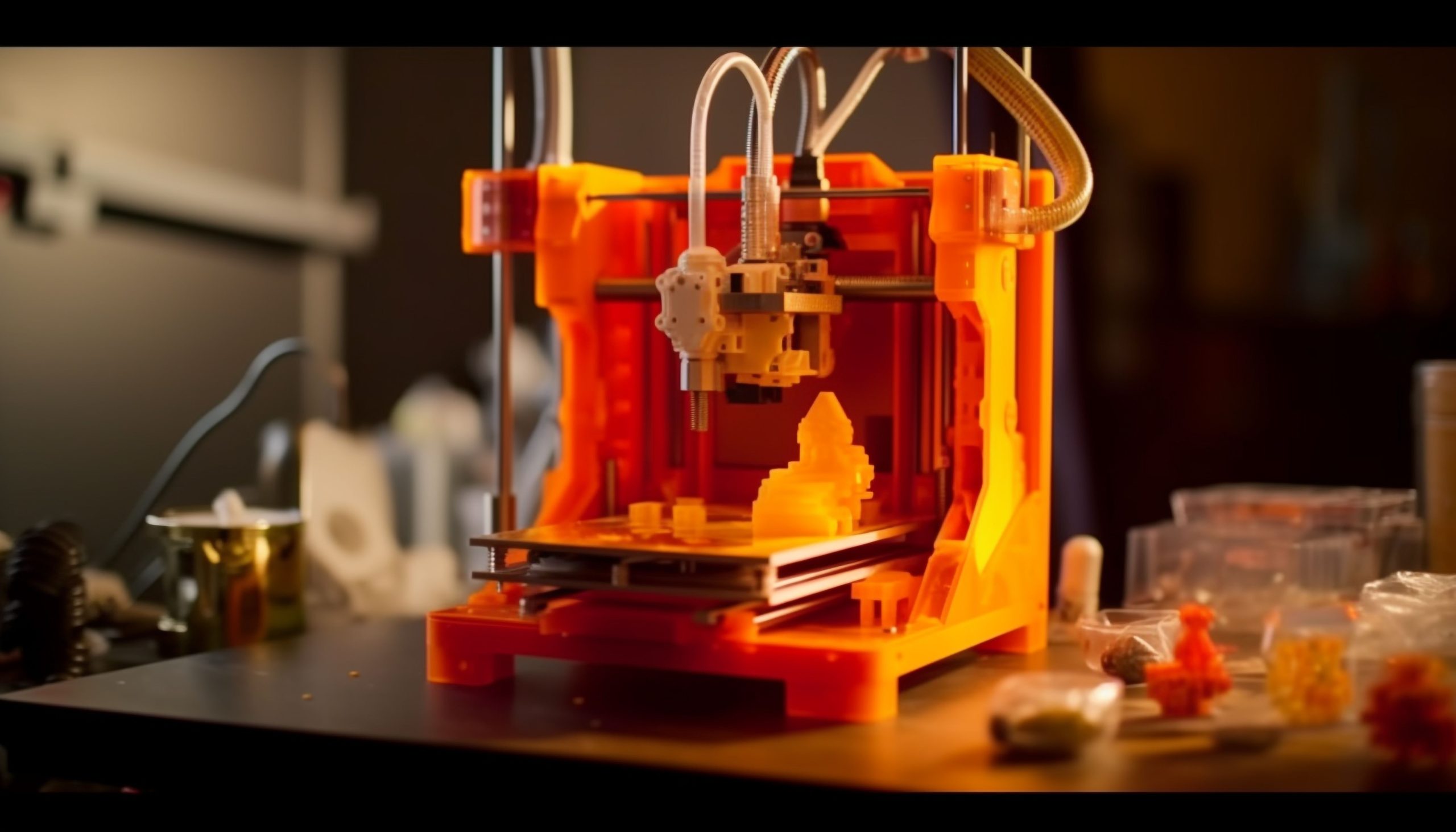

TriAnkle project: bioprinting tissue regeneration as a therapy for Osteoarthritis patients

One area of research that has been gaining momentum in the last decade is printing with biocompatible materials for tissue regeneration, also known as bioprinting.

Article courtesy of Lluís Quintana Frigola, Corporate Manager, Viscofan Bioengineering.

Bioprinting holds great promise for addressing the needs of osteoarthritis patients in a variety of ways (Markel Lafuente-Merchan, 2022). Osteoarthritis is a degenerative joint disease that affects millions of people worldwide and causes pain, stiffness and reduced mobility. Bioprinting offers the possibility to create tailor-made solutions for these patients, from the production of customised implants to the development of living tissue substitutes (Carlos Mota, 2020). Here are some ways in which bioprinting could contribute to alleviating the challenges faced by Osteoarthritis patients/improving the quality of life of Osteoarthritis patients:

1. Customised implants: Bioprinting makes it possible to create implants tailored to each patient’s specific anatomy. This means that implants can be designed to precisely match the contours of the patient’s joint, which can reduce the risk of complications and improve the overall effectiveness of the implant (Ethan Hau Yin Lam, 2023). Customised implants can also take into account variations in joint shape and size, optimising the fit and reducing the need for further adjustments.

2. Biomimetic materials: Bioprinting allows the use of biomimetic materials that closely resemble the body’s natural tissues. By mimicking the properties of cartilage and bone, bioprinted materials can better integrate with surrounding tissues, improving performance and reducing the risk of rejection. These biomimetic materials may offer a more natural and durable solution for osteoarthritis patients compared to traditional implants.

3. Tissue engineering: bioprinting makes it possible to manufacture living tissues that can potentially replace damaged or degenerated joint tissues. For osteoarthritis patients, this could mean the production of cartilage or bone tissue that closely resembles the patient’s own tissues, offering a regenerative approach to treating joint degeneration. These bioprinted tissues have the potential to promote healing and restoration of joint function, offering a more complete solution for treating osteoarthritis (Andreia M. Gonçalves, 2021).

4. Drug delivery systems: Bioprinting can also be used to create sophisticated drug delivery systems that can be integrated into implants or tissues to provide targeted and controlled drug release. For osteoarthritis patients, this could mean the development of implants that deliver anti-inflammatory drugs or other therapeutic agents directly into the affected joint, helping to control pain and inflammation more effectively. This targeted approach has the potential to improve treatment efficacy while minimising systemic side effects.

5. Regenerative therapies: Bioprinting has the potential to support regenerative therapies for osteoarthritis by creating platforms for the delivery of cells, growth factors and other biological signals that can promote tissue repair and regeneration. By providing an environment conducive to the body’s natural healing processes, bioprinted constructs may facilitate cartilage and bone regeneration, offering a more holistic approach to the treatment of osteoarthritis.

In short, bioprinting can revolutionise the treatment of osteoarthritis by offering personalised biomimetic solutions that respond to the specific needs of each patient. The TriAnkle project, a consortium of 12 partners, including OAFI, funded by the European Commission, is developing regenerative therapies based on bioprinting of collagen, cells and growth factors to treat cartilage and tendon problems (Quintana L, 2021). Although the field of bioprinting is still evolving, the potential to address the challenges of osteoarthritis is significant, and ongoing research and development in this area holds great promise for the future of orthopaedic medicine.

Bibliography

Andreia M. Gonçalves, A. M. (2021). Osteochondral Tissue Engineering: The Potential of Electrospinning and Additive Manufacturing. Pharmaceutics, Jul; 13(7): 983. doi:10.3390/pharmaceutics13070983

Carlos Mota, *. S.-E. (2020). Bioprinting: From Tissue and Organ Development to in Vitro Models. Chem Rev., Oct 14; 120(19): 11032–11092. doi:10.1021/acs.chemrev.9b00789

Ethan Hau Yin Lam, F. Y. (2023). 3D Bioprinting for Next-Generation Personalized Medicine. Int J Mol Sci., Apr; 24(7): 6357. doi:10.3390/ijms24076357

Markel Lafuente-Merchan, S. R.-A.-V.-M.-d.-B. (2022). Progress in 3D Bioprinting Technology for Osteochondral Regeneration. Pharmaceutics, Aug; 14(8): 1578. doi:10.3390/pharmaceutics14081578

Quintana L, T. c. (2021). Editorial TriAnkle project. Apunts Sports Medicine, Vol. 56. Issue 211. doi:10.1016/j.apunsm.2021.100363

Article courtesy of Lluís Quintana Frigola, Corporate Manager, Viscofan Bioengineering.

Image of vecstock in Freepik

Categories :